Applications

Let’s explore the endless possibilities of freeze drying together!

Freeze-drying technology has a wide range of applications in the food, agriculture and biotechnology industries. It not only reduces damage to the original ingredients, but also extends the shelf life of the product. Freeze-drying has unparalleled advantages in preserving the flavor, color and nutritional content of the original substance.

With our extensive experience in freeze-drying technology, we offer specialized solutions that can dramatically increase the value and consistency of your products. With our technical support, companies are better able to maintain product quality and expand the reach and profitability of their business.

Food

Freeze-drying technology is an indispensable tool in modern food processing. By removing water at low temperatures and in a vacuum environment, it preserves the nutritional value, texture and flavor of food while extending shelf life.

Pet Food

HUCHUAN® offers advanced freeze-drying technology to preserve the nutrients and flavor of pet food and extend the shelf life. The products are not subjected to heating and maintain the original quality, which is suitable for the production of all kinds of pet food.

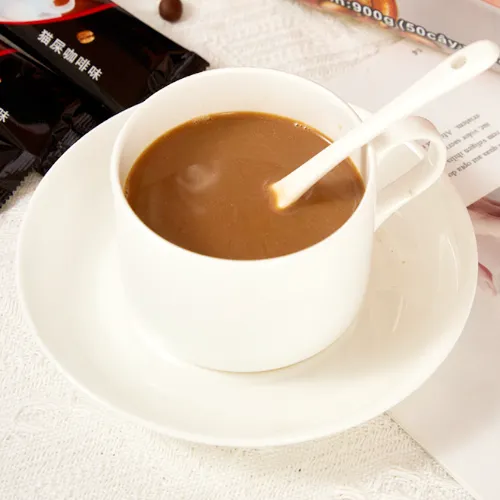

Coffee

Freeze-drying technology has revolutionized the coffee industry. By preserving the original flavor of coffee and extending shelf life, freeze-dried coffee has a stronger taste and longer-lasting aroma.

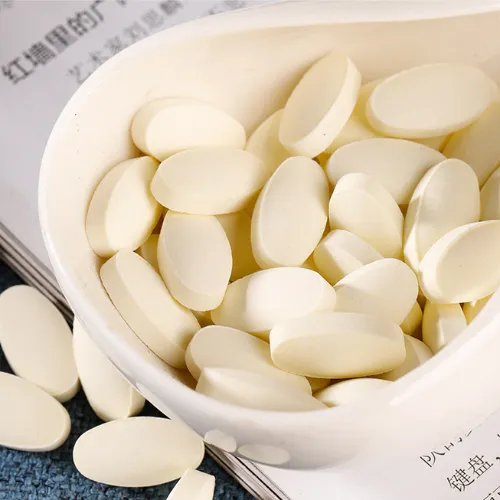

Nutraceutical

The use of freeze-drying technology effectively preserves bioactive ingredients and nutrients, ensuring high quality and long shelf life. Provides reliable processing solutions for nutraceutical production and promotes industry innovation and development.

Flowers

Retains original shape and nutrients through vacuum low-temperature dehydration process for perfect preservation of flowers, leaves and other plant material. Extremely low shrinkage of the product extends shelf life and is suitable for beauty products, bath products and other fields.

Taxidermy

The use of freeze-drying technology can effectively preserve the morphology and structural integrity of animal specimens, ensuring the permanent preservation of specimens. Both researchers and museum practitioners can rely on freeze-drying technology to achieve high-quality specimen processing.

Cannabis

Produces high-quality products by retaining more cannabinoids and terpenes through low-temperature vacuum dehydration processing. Fast production cycle, completed in 18-36 hours, saving time and cost. Maintains original color and size, reduces microbial content, ensures product quality.

Research and Development

HUCHUAN® provides advanced freeze-drying technology, which provides a reliable basis for biochemical research and product development, extends product shelf life, simplifies operational processes, and facilitates scientific exploration and innovation.

Freeze Drying Technology Applications

Freeze-drying technology is widely used in a variety of industries, including:

- Food industry: convenience food, fruits, vegetables, meat, fish, nutraceutical, coffee, tea, seafood, kimchi, etc.

- Pet food: freeze-dried pet food including freeze-dried dog food, freeze-dried cat food, freeze-dried pet snacks of various flavors and ingredients, etc.

- Flower and Animal Specimen Production: Production of various animal and plant specimens and handicrafts, and drying and preservation of animal tissues.

- Suitable for freeze-drying and preserving plasma, vaccine, biological products and herbal medicine.

- Scientific Experiments and National Defense and Aerospace: Used in aerospace food, scientific experiments and military food.

- Other fields: such as catalyst in chemical industry to improve efficiency, wet wooden cultural relics, drowned books and manuscripts, etc. with freeze-drying method, plant leaves, soil freeze-drying preservation and so on.

What are the advantages of freeze drying?

Freeze-drying has many advantages over traditional drying methods such as desiccation, drying, boiling, spray drying and vacuum drying:

- Freeze-drying is performed at low temperatures and is therefore particularly suitable for many heat-sensitive substances. For example, proteins, microorganisms, etc., without degradation or loss of biological viability.

- Freeze-drying at low temperatures causes little loss of some volatile components in the material, making it suitable for drying certain chemical products, pharmaceuticals and food.

- In the process of Freeze-drying, microbial growth and enzymatic action cannot take place, so the original characteristics can be maintained.

- Since the drying process is carried out in a frozen state, the volume is almost constant, the original structure is preserved and no concentration occurs.

- The dried material is porous and spongy and regains its original characteristics almost immediately after the addition of water.

- As drying takes place in a vacuum, oxygen is low and therefore some oxidizable substances are protected.

- Freeze-drying can remove more than 95-99% of water, so the dried product can be stored for a long time without deterioration.

- Freeze drying has a wide range of applications in food, agriculture, biology, research and other fields.

Freeze-drying production basic process

Raw material refrigeration preservation – raw material processing – according to the material characteristics of the pre-freezing – material dehydration sublimation drying -Selection, metering and packaging – Storage of finished products in warehouse.

Contact us

Talk to our team of engineers and experts and we will customize industry-leading freeze-drying solutions to ensure you get the best results in terms of production efficiency.

The HUCHUAN® team of engineers and experts is focused on providing professional and timely service to our customers, and we are here to help!