Nutraceutical Freeze Drying

Freeze-drying technology is of great importance in the nutraceutical industry. Freeze-drying can effectively retain the bioactive ingredients and nutrients in nutraceuticals while preserving their enzymatic activity, color, aroma and flavor, ensuring high quality and long shelf-life of the product.

Wide range of applications of freeze-drying technology in the nutraceutical industry

Freeze-dried plant parts such as seeds, hulls and kernels can be used as natural additives in nutraceuticals, enriching the nutritional content of the product and adding the benefits of natural botanicals. Fruits and green leafy vegetables can be used as raw materials for nutraceuticals after freeze-drying, retaining their rich nutrients and natural flavors, and providing a convenient and reliable source of raw materials for nutraceutical preparation.

Nutraceutical ingredients such as meat, fish, fluid products, dairy products, collagen, whey isolates, etc. can also be processed by freeze-drying technology to retain their nutrients and extend the shelf life of the products. Freeze-drying technology not only helps preserve the important ingredients and properties of nutraceuticals, but also expands the range of product applications, providing more diversified choices for health foods, dietary supplements and other products.

Freeze-drying technology provides an important processing means for nutraceuticals, preserves the nutrients and properties of the product, expands the application areas of the product, and promotes the continuous innovation and development of the nutraceutical industry.

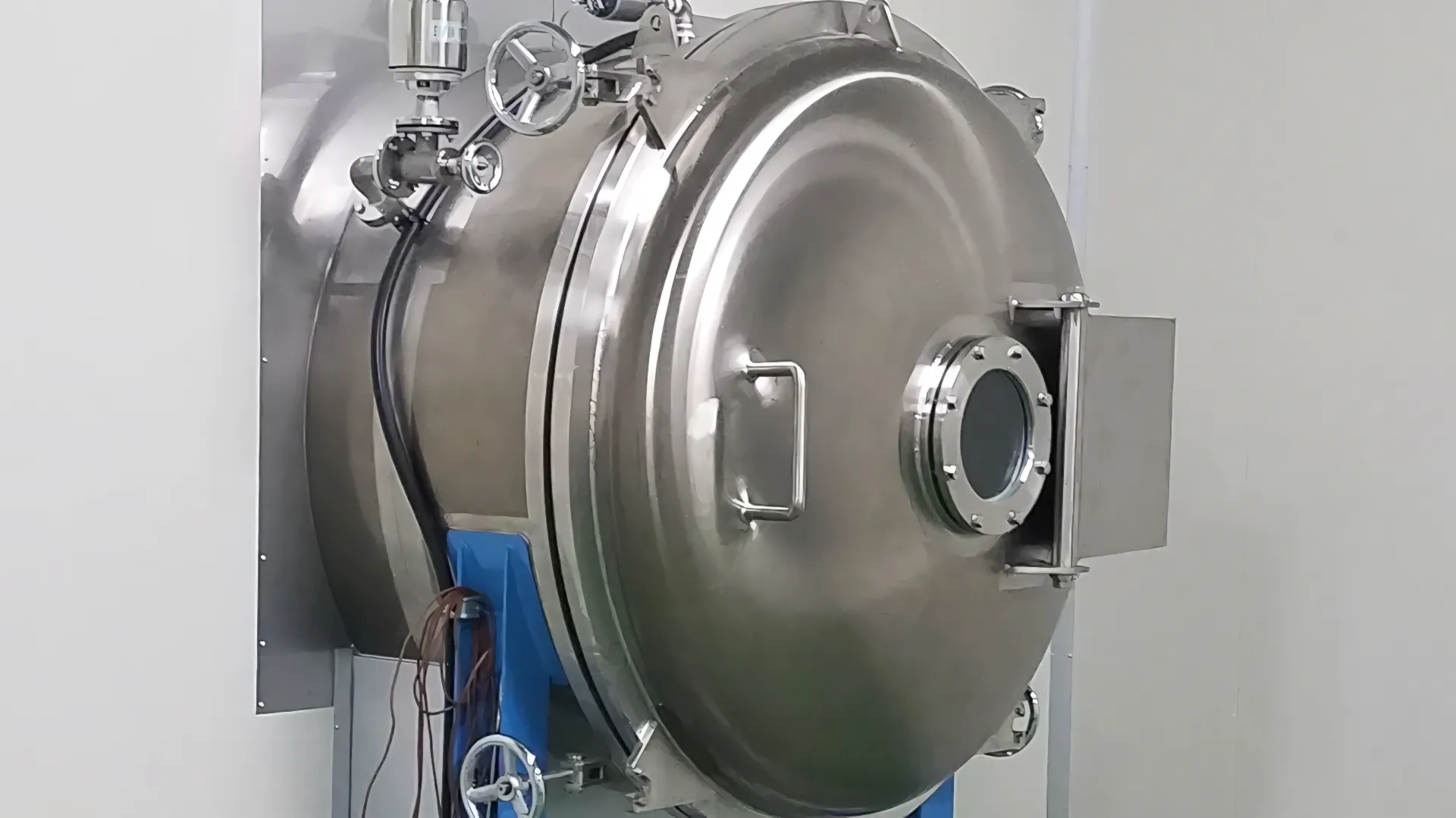

Nutraceutical Freeze Dryer Recommendations

Based on Nutraceutical Freeze Drying, we recommend HUCHUAN® Pilot Freeze Dryer and HUCHUAN® Commercial Freeze Dryer series for your choice.