Industrial Freeze Dryer

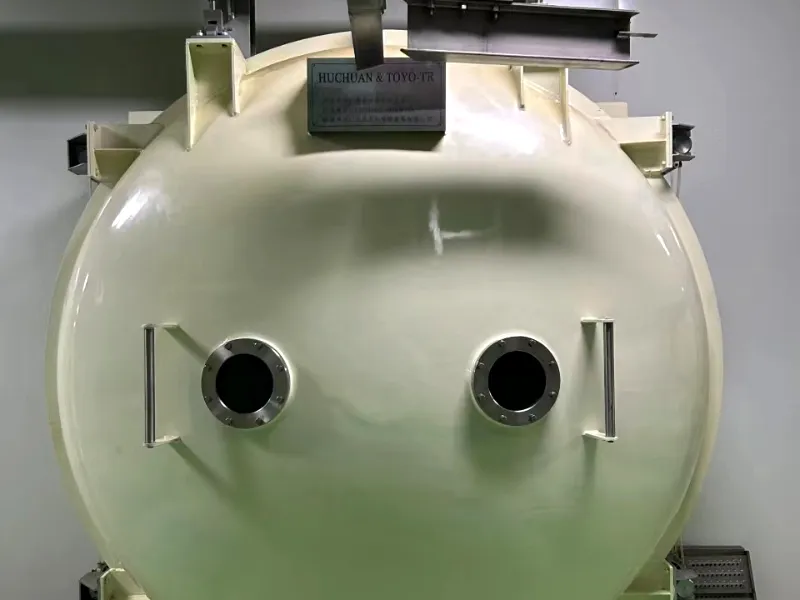

HUCHUAN® designs and manufactures industrial freeze dryers known for their professionalism, reliability and energy efficiency to meet the needs of large-scale industrial production. Its leading HUCHUAN® & TOYO-TR vacuum freeze drying concept has the advantages of economic benefits such as high batch yield, short drying cycle and low operating cost.

Our team of senior engineers and experts, with professional freeze drying knowledge and rich experience, can not only provide design, manufacture, installation, commissioning, training and after-sales service of industrial freeze dryers, but also assist you in freeze drying process research and development, and other turnkey project service packages.

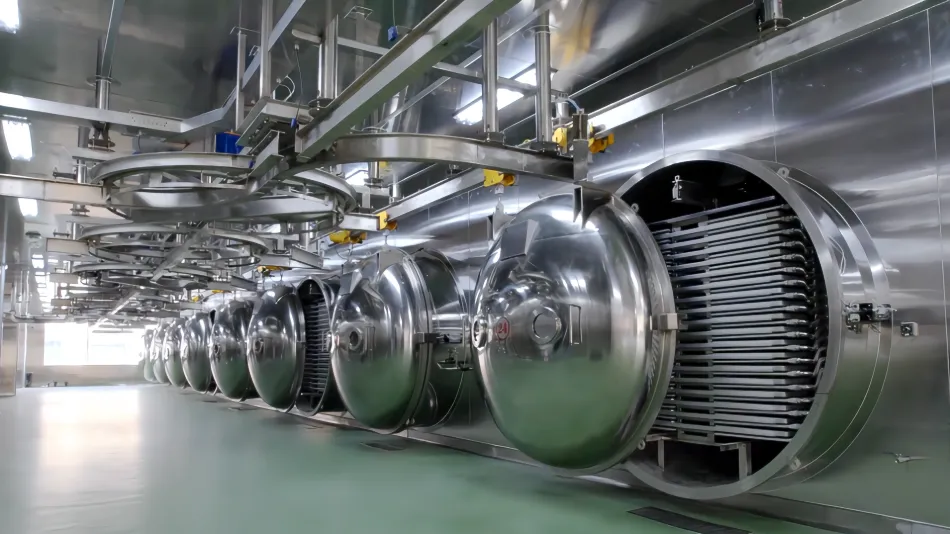

HUCHUAN® Industrial Freeze Dryers

The HUCHUAN® industrial freeze dryer series consists of five different main models to meet various production needs. Whether you need to upgrade your plant equipment or are planning large-scale industrial production, we will always provide you with satisfactory equipment and the most suitable freeze drying solution.

| Models | HTFD600L-50m²/R | HTFD1200L-100m²/RA | HTFD2500L-200m²/RA | HTFD2500L-200m²/RA | HTFD3000L-240m²/RA |

|---|---|---|---|---|---|

| Ice condenser capacity | 600L | 1200L | 2500L | 2500L | 3000L |

| Product tray area | 50㎡ | 100㎡ | 200㎡ | 200㎡ | 240㎡ |

| Number of product trays | 136 | 272 | 532 | 532 | 640 |

| Product trays size | 680mm x570mm x35mm | 680mm x570mm x35mm | 680mm x570mm x35mm | 680mm x570mm x35mm | 680mm x570mm x35mm |

| Number of trolleys | 2 | 4 | 7 | 7 | 8 |

| Condenser type | Inside of the drying chamber type | Inside of the drying chamber type | Inside of the drying chamber type | Independent type | Independent type |

| Drying chamber dimensions | Φ2.50m x7.00m (L) | Φ2.50m x11.00m (L) | Φ2.50m x17.50m (L) | Φ2.50m x12.50m (L) | Φ2.50m x13.80m (L) |

| Building requirement | 150㎡ | 200㎡ | 280㎡ | 280㎡ | 300㎡ |

| Peak power requirement | 57kw/37.7kw | 114kw/39.5kw | 203kw/86kw | 203kw/86kw | 270kw/90kw |

Disclaimer: While every effort is made to provide accurate information, it is subject to change at any time. Performance figures are calculated and may vary in use due to different products and formulations.

The sales price of the industrial freeze dryer includes design, manufacture, installation, commissioning, training and after-sales service.

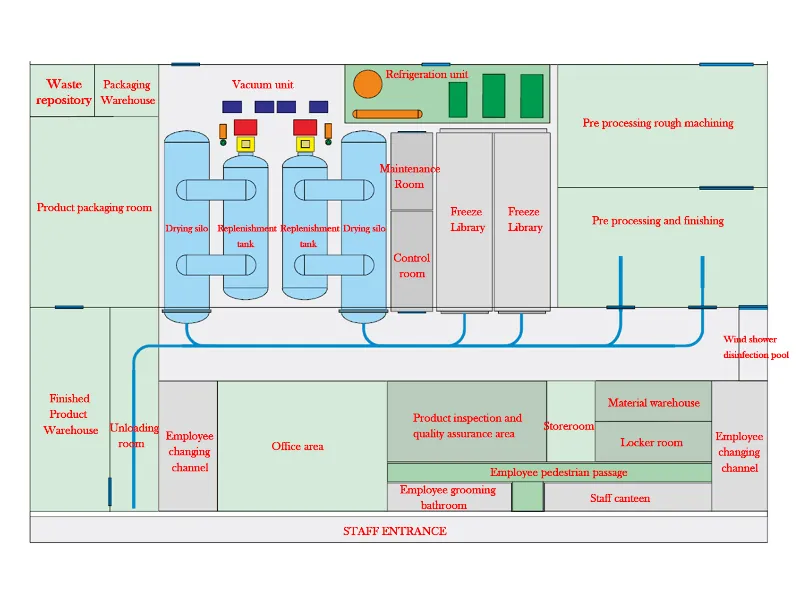

Industrial Freeze Drying Systems

HUCHUAN® Industrial Freeze Drying Systems save space, maximize productivity and reduce production costs. Carefully designed according to your site layout, our industrial freeze drying system will be perfectly connected with your production process.

1.Overhead rail transport system

The operator quickly transports the product to the required area by means of a sliding trolley on the overhead rail. The whole process is rationally designed, and the freezing room, drying chamber and product pallet loading and unloading areas are connected by the overhead rail, forming a close production process, saving labor and time.

2.Product freezing system

Products are quickly frozen in the freezing room, and a 6~8 hour preparation shift can provide enough freeze-dried products for 24 hours. Freezing adopts the principle of “first in, first out”.

3.Drying sublimation system

Automatic control of drying cycle for each batch. Just close the door of the drying chamber, set the process parameters and press the start button to enter the drying process, minimizing manual intervention and supervision.

4. Heat supply system

The controlled temperature range from room temperature to 90°C is precisely monitored and controlled to optimize the drying process.

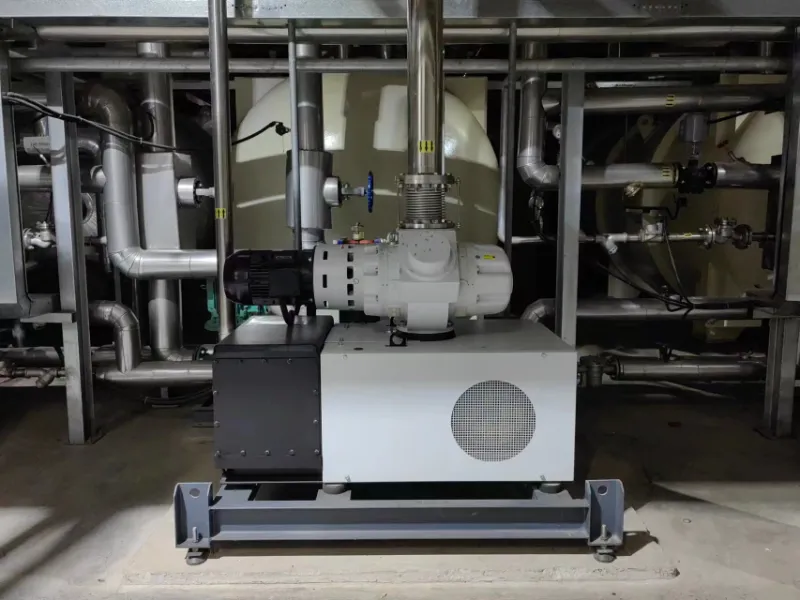

5. Vacuum system

High efficiency, high flow vacuum pumps typically reach the required vacuum level in less than 15 minutes. For products with a low freezing point, even more precise control is possible.

High efficiency, high flow vacuum pumps typically reach the required vacuum level in less than 15 minutes. For products with a low freezing point, even more precise control is possible.

6. Refrigerationg system

Adoption of industrial compressor with high efficiency cooling. When multiple units are operated in parallel, each condenser can share a common system, staggered operation, significant energy saving.

7.De-icing system

By using water flushing batch type ice melting, utilizing the batch interval time, the ice melting will be finished in about 40min without taking up the drying time. The water flushing de-icing system is low cost and easy to operate.

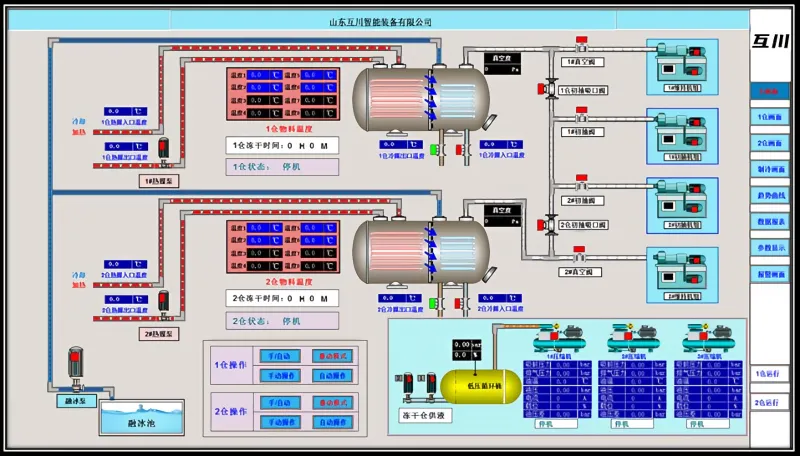

8.Control system

Advanced PLC industrial control system, support manual/automatic switching, with real-time operation parameter control and process curve printing function, all data can be stored and retrieved. The control system can ensure that the freezing, drying and related heating, vacuum and cooling systems work efficiently and harmoniously, so that the machine is in the best operating condition.

Standard Features

Structurel

- All subsystems are independently designed, shipped separately and assembled on site.

- The overhead conveyor is a heavy duty H-beam monorail for strength and stability.

- The industrial freeze dryer program includes the construction of the freezing chamber.

- The Freezing Room is designed to be self-contained and can be quickly assembled on site.

- The drying chamber is constructed of carbon steel or 304 stainless steel for durability and sanitation.

- The drying chamber is a cylindrical vessel with a door at one end and an observation window on the door.

- The product contact part is made of food grade material to reduce the risk of product cross contamination.

- The shelves and trays are made of anodized aluminum alloy for high thermal conductivity.

- The heating plate of the shelves adopts double-sided radiant heating method, which can dry the products evenly.

- The heating medium of the shelves is distilled water, which will not contaminate the products even if there is a leak.

- The condenser is installed inside the drying chamber or independently on the side.

- The condenser and shelves are separated from the wet and dry areas to prevent product contamination in the production process.

- PLC and touch screen control system, realize intelligent operation and monitoring.

Performance

- Shelf temperature range normal temperature to 90⁰C

- Shelf heating rate 1~2⁰C/min.

- Condenser final temperature -40⁰C

- Condenser cooling to -30⁰C < 30min

- Maximum drying chamber vacuum <4Pa

- Drying chamber evacuation atm to 133 Pa in <15 min (no load)

Design Features

HUCHUAN&TOYO-TR concept

According to the leading HUCHUAN&TOYO-TR vacuum freeze drying concept, the whole industrial freeze-drying system is scientifically designed according to the six elements of time, temperature, pressure, material flow, personnel flow and process flow:

- Minimize product loss

- Minimize energy and labor costs

- Maximize production efficiency

- Maximize equipment reliability and ease of use.

Economic advantages

The reliable operation of our industrial freeze drying machine provides you with unique economic and technical advantages:

- The lyophilization process results in stable products with a long shelf life.

- Freeze-dried products are stable at all temperatures and do not require complex cold chain distribution systems.

- Freeze-dried products are lightweight and easy to handle, significantly reducing transportation costs.

Efficiency advantage

HUCHUAN® has used its extensive knowledge and experience in freeze drying to design an industrial freeze dryer that brings you the advantages of fine efficiency:

- Scientific and efficient design

- Simple and reliable operation

- Fast and uniform drying

- High sublimation capacity

- Precise temperature and vacuum control

- Minimal product loss

- PLC control system opens/closes all major components and valves

- Freeze drying recipes can be programmed, stored and modified

- Units can be remotely monitored and controlled

- Easy to clean and maintain

Industrial Freeze Dryer Applications

HUCHUAN® is the leading industrial freeze dryer manufacturer in China. The industrial freeze dryer series sold by HUCHUAN® are carefully designed and widely used in the food, agricultural and bio-engineering industries where large-scale industrial production is required, and can freeze dry a wide range of products including, but not limited to Instant coffee and tea and other extracts and liquids, vegetables, fruits and berries, meat and seafood products, ready meals, dairy products, pet food and many more products on the market.

HUCHUAN® provides a full range of services worldwide. We not only sell standard models, but also provide customized services, combining your industry knowledge and our technical expertise to design and develop new industrial freeze dryers. We can customize the drying chamber size, shelf space, condenser capacity and installation method of the industrial freeze drying machine according to your needs, which will allow you to process a wide range of products with confidence and help you gain a competitive advantage in the market.

The sales price of the industrial freeze dryer includes design, manufacture, installation, commissioning, training and after-sales service.

Contact us

HUCHUAN® team of engineers and experts are focused on providing professional and timely service to our customers, and we are always here to help!