Knowledge Bases

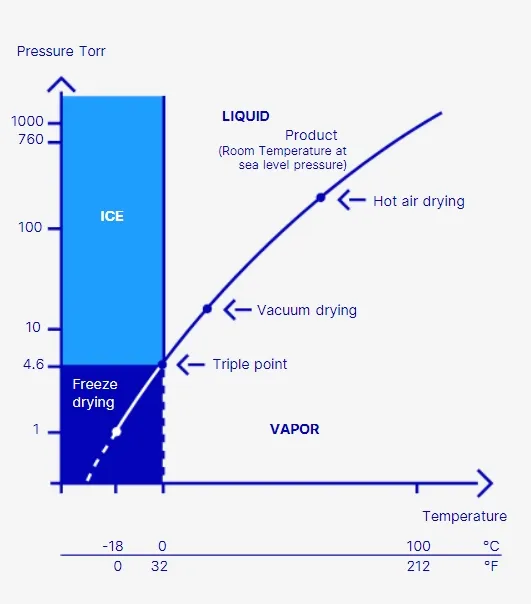

Water has three phases: solid, liquid and gas, at a temperature of 0.01℃ and a pressure of 610Pa, water is a three-phase coexisting state, and the three-phase line is called (OS) sublimation curve, (OL) dissolution curve and (OK) vaporization curve respectively, and the phenomenon of sublimation is the process by which a substance is transformed into a gaseous state from a solid state without going through the liquid state directly. In the pressure is lower than 610Pa, if the ice is heated, the ice can only cross the liquid state directly sublimation for the vapor state, vacuum freeze drying is based on this principle, and this is the theoretical basis of freeze drying.

Freeze drying is the use of the principle of the three-phase point of water, first through the low temperature will be frozen in the product of water to form solid ice, and then in the vacuum environment will be sublimated directly into vapor, avoiding the existence of the liquid phase. This creates a very gentle drying process that preserves the form, color, taste and nutrition of the product.

A freeze dryer is a device that pre-treats water-containing raw materials and then rapidly freezes them at temperatures as low as approximately -30°C. The water is then sublimated and dried under vacuum.

Freeze drying is a method of drying substances without changing their nature or other substances that must be preserved. It is widely used in the confectionery industry, biochemistry, medical research and the food industry, where important substances need to be preserved. The method starts by freeze-drying the raw material through freezing and then removes the water through a sublimation process, allowing the substance to be dried.

A freeze dryer, also known as a freeze drier, works by freezing the material below its eutectic point and then sublimating the ice directly into water vapor in a vacuum environment to achieve dryness. This process is divided into three stages: pre-freezing, sublimation drying and resolution drying.

Pre-freezing: This step is to freeze the material below its eutectic point quickly in order to fix its structure.

Sublimation drying: In a vacuum environment, ice changes directly from solid to gas, a process called sublimation. As the ice sublimates, the water in the material is removed.

Resolution drying: When the ice in the material is completely sublimated, it is necessary to further remove the residual moisture, this step is called resolution drying.

The freeze dryer is mainly composed of refrigeration system, vacuum system and control system. The refrigeration system is responsible for freezing the material, the vacuum system creates the environment required for sublimation drying, and the control system is responsible for the automatic operation of the whole machine.

In the freeze drying equipment:

- The drying chamber is where the raw materials are placed, cooled and dried.

- An ice condenser is used to collect the sublimation vapors.

- A vacuum pump is used to maintain the pressure in the drying chamber.

- A compressor is used to provide constant cooling energy to the condenser to ensure continuous condensation of the vapors.

- The control system ensures the automation of the freeze drying process.

Since freeze drying technology can preserve the original structure of materials and can be stored for a long time at room temperature, it is widely used in the fields of food, pharmaceuticals and biological products. For example, in the food industry, freeze drying technology can preserve the original flavor and nutritional value of food; in the pharmaceutical industry, freeze drying technology is used in the manufacture of drugs and vaccines; in the field of biotechnology, freeze drying technology is used for preserving biological samples and cells and so on.

Preservation of original structure: During the freeze drying process, the original structure and shape of the material is preserved.

Preservation at room temperature: As the water has been removed, the freeze-dried material can be preserved at room temperature for a longer period of time.

Reduce oxidation: Drying under vacuum environment can reduce the occurrence of oxidation reaction.

Energy saving and environmental protection: compared with other drying methods, freeze dryer consumes less energy, and there is no waste gas, waste heat, etc. generated.

Despite the many advantages of freeze dryers, some problems may be encountered during use, such as condenser contamination and unstable vacuum. Solutions to these problems include regular cleaning of the condenser, checking whether the vacuum system is working properly and so on. In addition, in order to get a better drying effect, attention should be paid to the ratio and loading amount of materials.

Freeze-dried food is the abbreviation of vacuum freeze -dried food, also known as FD (Freeze Dried) food.

Vacuum freeze drying is a physical dehydration technique. But unlike frying or baking and making powders with spray drying.

Food freeze drying is to pre-freeze fresh food such as vegetables, meat, fruits, etc. quickly, and in a vacuum state, the water in the food from the solid state sublimation into a gaseous state, and then by the resolution of drying to remove part of the combined water, so as to achieve the low-temperature dehydration and drying. The whole freeze-drying process mainly includes three stages: pre-freezing, quick-freezing and vacuum drying.

Due to the special treatment process of freeze-drying, the color, aroma, flavor, shape and nutrients of the original fresh food can be maintained to the maximum extent, and it can be preserved for more than 5 years at room temperature without preservatives. At the same time, due to the finished product in addition to most of the water, has the advantages of light weight, easy to carry and transportation, etc., can be directly eaten, can also be slightly processed, within a few minutes will be restored to fresh food, can be said to be in the food industry is very great potential for development.

Freeze-dried food has been vigorously promoted and popularized in recent years, and the processing technology and marketing have gradually matured. In addition to home and restaurant, the technology is also widely used in mountaineering, travel, scientific research, munitions and many other industries, and its advantages and features have been fully utilized.

Vacuum freeze-drying technology, currently the most advanced processing technology for food preservation and storage in human life, the main features:

- Preservation of food color, aroma, taste, shape.

In the freeze drying technology process conditions, the maximum preservation of food color, aroma, flavor, shape and nutrients and active substances. Freeze-dried food unique processing technology, not only can retain the food “flesh”, but also retain its “soul”.

- Preservation of food nutrients

Freeze-dried food, such as aerospace food is essentially the same as ordinary food on the ground, which is to provide energy and nutrition for the human body, so the nutritional value of freeze-dried food is crucial. Take spinach as an example, vitamin C can be retained by 95% after freeze-drying, while hot air blow-drying can only retain 55%, shade-drying only 7%, and sun-drying even less, only 4%.

- Extend shelf life

The dehydration rate of freeze-dried food is as high as 95%-99%, and it can be stored and transported at room temperature after packing. There is no need to add any

In sealed package without adding any antioxidant, it can be stored at room temperature for 5 years, and under the condition of package filled with protective gas, it can be stored at room temperature for even 10 years.

- Convenient for logistics and transportation

Due to the light weight and small volume of dehydrated products, take strawberries as an example, the weight of freeze-dried products is only 1/8 of that of fresh products, which greatly reduces the logistics cost and is very convenient for transportation.

It depends on the product, but for general food, the freezing method can preserve food for up to 2 years, the filling method can preserve it for 3 years, the drying method can preserve it for up to 4 years, and the freeze-annoying method can preserve food for up to 25 years. This shows that freeze-drying methods have many outstanding advantages over traditional methods.

Depending on the product, most products can be made in half a day to a day.

- **Product Demand Analysis**: First of all, it is necessary to define the freeze-drying demand of the product, including the type of material to be processed, volume, shape, humidity and other characteristics, as well as the required final product specifications.

- **Process Flow Design**: Design the process flow of freeze drying, including the stages of freezing, primary drying, secondary drying and recrystallization. Ensure that the temperature, pressure and time control of each stage meets the product requirements.

- **EQUIPMENT SELECTION**: Select freeze-drying equipment suitable for HUCHUAN&TOYO TR’s needs, taking into account factors such as processing capacity, energy consumption, and automation level. Possible equipment includes batch freeze dryer, continuous freeze dryer, etc.

- **System Integration**: Integrate the freeze drying equipment with HUCHUAN&TOYO TR’s existing systems to ensure that the equipment will work seamlessly with other process equipment and control systems.

- **Energy Management**: Design an energy management system to optimize the energy consumption of the freeze-drying process, reduce energy costs, and consider the use of renewable energy sources.

- **Quality Control**: Develop a quality control program to ensure that the quality of products in the freeze-drying process meets standards, and implement appropriate testing and monitoring measures.

- **Safety and environmental protection**: Consider the safety and environmental protection issues in the freeze-drying process, and take necessary measures to ensure the safety of operators and the environment, as well as to comply with relevant environmental regulations.